I lately acquired the chance to tour the Chris King Precision Elements Manufacturing facility headquarters in NW Portland. Though I’ve been dwelling in Portland, Oregon for many of my life, I’d by no means visited the HQ and manufacturing facility till a pair weeks in the past after I was given a private tour of the ability by Jay Sycip, Chris King’s head of promoting. Regardless of having zero expertise working in manufacturing, and being an enough however definitely not professional bike mechanic, the expertise was nonetheless a captivating and pleasing one. And, having lately been testing the brand new Chris King ARD44 carbon all-road wheels, I used to be eager to see what goes into making these excellent wheels firsthand.

The tour started with a historical past of Chris King parts, highlighting the corporate’s breakthroughs and milestones on its path to turning into a legendary manufacturing firm. The show instances stuffed with componentry served as not solely a timeline of Chris King however in some ways of the bike {industry} as an entire, as King focuses on the components which have seen essentially the most change over the past 40 years of body evolution in each street and MTB. Beginning with a 1” threaded headset and shifting by means of time to the brand new Aeroset and R45D hubs, it’s a spirited begin to the tour that offers some high-level perspective on how influential and but adaptive this firm has been.

The King facility hasn’t all the time been house to ultra-refined wares, although. Sycip tells me that Folgers Espresso was as soon as floor and distributed out of this constructing. Fortunately that odor has been changed by aluminum and the vegetable oil that’s used to lubricate the equipment, and Stumptown Espresso is on the market within the cafe.

We begin in an space that accommodates aluminum inventory, which is within the type of lengthy rods that may ultimately shed a major quantity of fabric to turn into completed parts. That extra materials is consolidated into massive pucks to make recycling viable. Based on Sycip, if the fabric wasn’t compacted, its quantity would fill a lot of the ability. King makes certain that every puck is recycled, which is an instance of its well-documented document of being a sustainable firm. Subsequent to the aluminum inventory is a fenced-off space devoted to testing new tooling earlier than it’s applied on the store ground. It’s run by a fellow whom Sycip tells me has been on the firm for 30 years, and relocated to Portland with the corporate when it moved operations from its former house in Redding, CA.

Like every manufacturing facility, there’s an interaction between highly effective equipment, and the human skill to research and manage. Within the King manufacturing facility although, there’s an nearly heat and fuzzy feeling, because it’s simple to watch items of aluminum being reworked into purposeful artwork that may sooner or later grace lovely bicycles. I’m particularly eager to see the manufacturing of hub internals, as I’ve been testing the ARD44 wheels that characteristic the R45D hubs.

Peering by means of home windows splattered with vegetable oil, I watch as hub shells are bored out as skinny as attainable, middle lock splines and freehub our bodies are carved, and drive rings are sculpted. Finally, I watch as a batch of hubs are cradled inside a chamber and laser etched with the Chris King emblem. All the course of feels intimate and joyful, however on the identical time, it’s clear that persons are working arduous, doing issues completely or as near good as is humanly attainable.

Accuracy is the central theme of Chris King’s manufacturing course of, which means that the machining tolerances of all of the items that match collectively inside King hubs, headsets, and backside brackets are extraordinarily exact and that precision is consistently being verified by handbook measurement at each section of the method. In lots of instances, each tenth half to complete a given machining course of is measured to make sure that the machine is working inside tolerance.

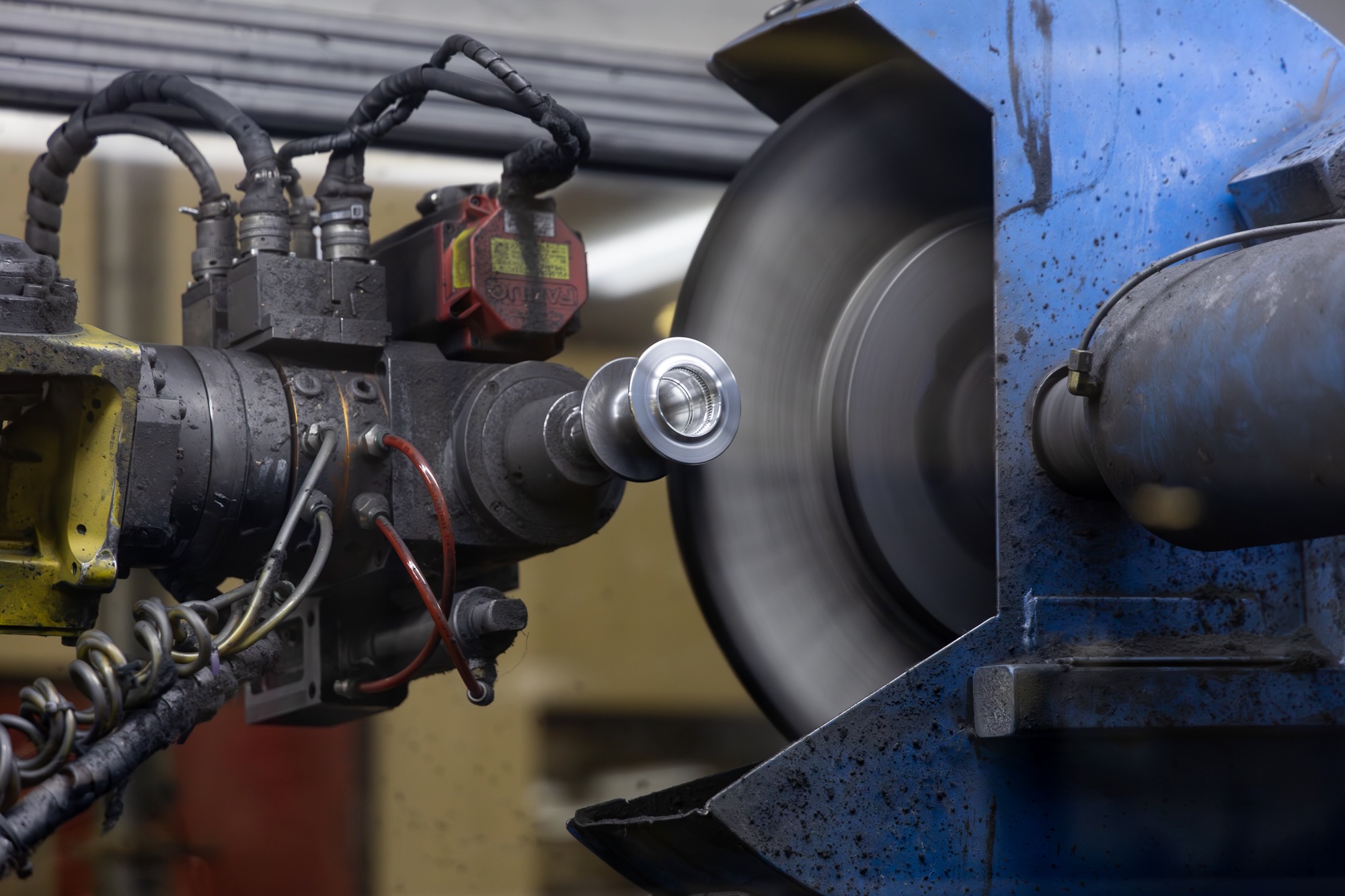

One of many extra satisfying stops of the tour was to observe an enormous robotic pluck hub shells off of a tray earlier than spinning round to carry them as much as certainly one of a sequence of high-speed sprucing wheels, rotating the hub shells subtly to make sure each nook and cranny of the floor was evenly polished. In different components of the ability, totally different levels of sprucing are being finished manually, or by submerging components in large tubs of walnut media that churn all through the day.

As soon as a hub is drilled for spokes and anodized, it’s what it’s. So, King pauses manufacturing of hubs at numerous levels, primarily based on what’s been bought and must be replenished. Seeing parts – particularly hub shells – at numerous levels of producing was seductive. Earlier than being anodized and drilled for spokes, the hub shells are quietly alluring, sitting in crates on shadowy shelving, gleaming proudly, ready their flip. On this almost-finished state, it’s simple to see why so many customized and small batch frames find yourself with King hubs – their natural form and timeless appears can absolutely tie a motorbike collectively visually.

I got here away from this tour with a brand new appreciation of the phrase “You get what you pay for”. What you’re paying for when shopping for a Chris King element is an uncompromising dedication to precision in manufacturing and worker care. The operation struck me as being environment friendly by means of persistence and forethought, not by frantically paced output that burns folks out. Even with the usage of extremely highly effective equipment, this manufacturing facility strikes at a deliberate and methodical tempo. The lean crew of employees is tremendous centered, performing repetitive duties as if it have been a surgical process. Everybody appears comfortable to be there and is genuinely pleasant and excited about discussing what they’re doing.

Staff are provided many perks, most of which deal with using extra. First, they merely receives a commission to commute to work. Whereas this was once offered within the type of meal credit, it’s now money that’s added to their paycheck. The locker room has well being club-level services together with a nifty air flow system that pulls air by means of the lockers to dry out clothes that will get damp on the morning commute. Full tune-ups and different mechanical help for worker bikes can be found within the service and guarantee division. Above the store ground is a snug cafe space, and a main-level hall is lined with ping-pong tables the place issues get fairly rowdy every single day at round 3:00.

Visiting the wheel constructing space, I watch as a set of the brand new ARD44 wheels are within the last levels of manufacturing, being trued and dished. The edges, that are product of fibers that may be recycled, mix with the R45D hubs to create a shocking wheel that’s each on the chopping fringe of know-how and appears purely timeless and fashionable on the truing stand. However how do they experience?

Chris King ARD44 Fusion Fiber Street Wheels Overview

Chris King’s first foray into carbon fiber street wheels is in some ways precisely what I anticipated from the model – a supremely refined, faultless, and delightful wheelset that feels prefer it simply would possibly final ceaselessly. One of many greatest tales right here is the innovation within the rim of the ARD44, which consists of a fabric made by a Utah-based agency known as CCS Composites and generally known as Fusion Fiber. These carbon rims use a thermoplastic resin, as an alternative of the thermoset resin that has till now been used to mould most carbon fiber rims. This thermoplastic resin course of claims to boost the fiber’s skill to soak up affect and vibration, and on the street, makes the ARD44 rim magnificently comfy, maneuverable, and regular over the roughest surfaces.

Fusion Fiber was first utilized to MTB and gravel-specific rims by corporations like Forge+Bond and Revel, and the Chris King ARD44 is the primary street wheelset to make the most of this new tech. Not solely are they tremendous comfy for his or her 44mm depth, however the thermoplastic resin makes the edges recyclable when the time comes, which by the texture of the ARD44 wheelset, will in all probability be lengthy, lengthy after you’ve moved onto a brand new bike.

Apart from buttery experience high quality, the opposite arresting characteristic of the AR44D is its unwavering stability. Within the context of deep-section carbon wheels, “stability” is usually related to a rim’s skill to deal with hectoring crosswinds. Deep-section carbon wheels of yesteryear have been notoriously sketchy within the wind as a result of fast-moving air would detach from the rim floor moderately abruptly, kicking off a ripple impact within the entrance finish of the bike, inflicting the rider to really feel like their entrance wheel was being pulled out from underneath them in an unpredictable method.

Extra lately, advances within the dimensions and profiles of carbon rims have dramatically improved crosswind stability industry-wide, however some rims nonetheless really feel extra steady than others on this state of affairs. In various wind situations, King’s ARD44 rim is essentially the most stable-feeling rim deeper than 30mm that I’ve ever examined. The ARD44 merely doesn’t wobble or expertise any lateral pulling or pushing as they reduce a path by means of gusty situations. Maneuvering stability can be top-notch, bringing new ranges of confidence and management to technical descents on less-than-ideal pavement and gravel.

Moreover, the ARD44 is audibly extra stealthy than many different carbon rims. Whereas some racers love the walloping “whoosh-whoosh” of many deep-section rims, I shortly turned a fan of how far more of the world round me I might hear when using the ARD44. This can probably be attributed to the spectacular damping properties of Fusion Fiber which appears to mute noise in addition to it does vibration.

The ARD44’s hookless bead wall, 25mm inner, and 30.5mm exterior width will possible attraction extra to the all-road and gravel crowd who run barely wider tires. King does state that the ARD44 are “aero optimized” for 28-30c tires and claims they will accommodate tires as much as 47mm broad. That mentioned, based on ETRTO steering, street riders can safely run 29c tires with strain within the 70 PSI vary, with none issues of safety, so I’m sticking with that. However, we’re certain that the parents at Chris King have finished their analysis and testing, and for more information on tires and the ARD44, you may learn Chris King’s tire compatibility assertion right here. And sure, there are some tires on the market labeled 29c, such because the ENVE SES, to call a favourite of mine.

Moreover, the ever-increasing selection of supple and hookless-compatible street tires signifies that one of many main knocks towards hookless – their incompatibility with clincher tires – is turning into much less of a difficulty. No matter public opinion on hookless rims for street using, a few of the greatest names within the {industry}, like ENVE, Zipp, Large/Cadex, and now, even Chris King, are on board with hookless street. Backside line, should you’re not comfy using hookless rims on the street, that’s honest, there are many different choices. However given the truth of 1000’s of hookless rims being safely used on the street inside the pointers of ETRTO, we’ll preserve seeing them on most of the finest street wheelsets in the marketplace, the ARD44 included.

Transferring to the remainder of the ARD44 construct, we discover certainly one of Chris King’s finest parts, the R45D hub, which gives one other sort of stability that may be felt by means of the bike’s drivetrain. With 45 factors of simultaneous engagement, the Ringdrive system within the R45D hub brings a gloriously fast, {smooth}, and sure, steady feeling to hopping out of the saddle and hitting the fuel arduous. After watching all the person items being machined within the manufacturing facility, it was not stunning that the ARD44 wheels really feel completely anchored and balanced by the R45D hubs. I used to be even impressed with R45D hub’s engagement after using the DT Swiss 240 Star Ratchet system for a very long time. Whereas the DT Swiss system can be glorious, there’s a markedly extra instantaneous and {smooth} response from the R45D rear hub throughout massive accelerations.

On the subject of hubs, the ARD44 wheels may be ordered along with your selection of Shimano HG, Shimano Microspline, and SRAM XDR freehub our bodies. They arrive with smooth-rolling chrome steel bearings, and consumers have the choice to improve to ceramic bearings for a $110 enhance in worth. In typical Chris King trend, you can too select between 10 totally different anodized shade choices should you’re making an attempt to paint coordinate in your dream construct.

The hubs and rims are laced along with high quality Sapim CX-Ray bladed J-bend spokes. These spokes assist to cut back aero drag and improve that comfy experience high quality. Plus, they need to be fairly simple to seek out should you ever want to switch one. The ARD44 rims weigh 435 grams, and the whole wheelset is available in at 1525 grams. Whereas these are definitely not competing for best-in-class weight figures for a wheelset at this worth level, it’s essential to do not forget that the ARD44 isn’t designed round a myopic deal with weight. These are wheels which might be meant to offer consolation. stability, and are constructed to final a lifetime.

To that finish, King gives a wonderful lifetime guarantee that’s easy to know and use. Assuming you’re the unique proprietor, should you inflict hurt in your ARD44 rims, you may ship them again to Chris King for a brand new rim and rebuild utilizing the prevailing hub – which may also obtain an overhaul on the identical time – they even choose up the price of transport each methods. What this guarantee means in follow is that these rims are bombproof. Chris King doesn’t desire a pile of cracked rims getting changed totally free, in order that they solely supply this degree of assist as a result of they belief the failure fee will likely be extraordinarily low.

At $2850, these are undoubtedly a high-end wheelset, however the worth of the ARD44 is aligned with different premium street wheel choices. And, although they might not be the lightest, they’re impressively comfy, steady, and elegant-looking all-around street wheels made to the best requirements and meant to final a lifetime in your ceaselessly bike.