Compliance this, compliance that. Within the biking world, we hear the phrase compliance fairly often. Handlebars, particularly, are one of many parts the place the phrase will get thrown round rather a lot, with varied manufacturers claiming totally different ranges of compliance and related advantages to utilizing their merchandise. However what does that actually imply and what affect does it have on efficiency in the actual world? And, since there’s no standardized handlebar compliance check or ranking scale, how will we truly know the way totally different fashions examine when it comes to stiffness/compliance?

To study extra, we teamed up with Faction Bike Studio for mountain bike handlebar compliance testing. After testing the compliance of 42 handlebar fashions in Faction’s lab, we cherry-picked a small choice as a consultant pattern of the various ranges of compliance throughout the spectrum for blind rider testing to see how their variations translate on the path. Take a look at the video above and maintain studying for somewhat background on this undertaking, what we discovered, and Faction Bike Studio.

What’s Compliance?

The phrase compliance is outlined by the Merriam-Webster dictionary as: “the flexibility of an object to yield elastically when a drive is utilized.” Whereas it means barely various things relying on the context after we’re utilizing it in relation to physics, it basically is the property of a fabric or object deforming or flexing beneath load. Mainly, it’s the other of stiffness.

Lately, compliance has change into a well-liked buzzword within the bike trade that’s usually used to explain merchandise which can be supposed or claimed to offer a sure degree of forgiveness with the aim of enhancing consolation or management. Manufacturers use this phrase to explain all the things from bike frames, saddle rails, and wheels, to seemingly easy parts like handlebars.

Whereas there are many riders on the market who don’t assume twice about their handlebar, there are many people who notice that there are vital variations and efficiency traits among the many many manufacturers, fashions, supplies, and shapes of bars. Preferences differ, after all, with many riders preferring one thing stiff for super-precise dealing with and most management, others preferring one thing extra compliant to take the sting off vibration and affect, and loads of folks aiming for the completely happy center floor between the 2 extremes.

Whereas compliance can undoubtedly play a serious position in enhancing consolation by absorbing some affect and vibration, there are additionally different components to contemplate relating to handlebars. Modifications in geometry (rise, upsweep, and backsweep) and even the setup of your controls can have an effect on your physique place and wrist alignment. Selecting the best grips will also be a think about getting the best match on your arms or including some cushioning and vibration absorption. Moreover, correct suspension setup, the best tire strain, or extra compliant wheels may assist to scale back vibration and suggestions that may in any other case be transmitted to your higher physique.

Undertaking Background

We’ve been involved with Faction Bike Studio for the previous couple of years, slowly however absolutely developing with a plan to collaborate on a undertaking collectively. After fairly a little bit of backwards and forwards, a plan lastly began to take form in March of 2023. It was truly former Bikerumor workforce member, Jessie-Could Morgan, who kicked off the handlebar compliance testing undertaking at the moment.

The premise was pretty easy. Collect a wide array of handlebars and carry out a standardized, constant, repeatable flex check on all of them in Faction’s check lab to find out their deflection, or degree of compliance, in a managed setting. Armed with that data, the subsequent step was to do some blind rider testing to see if these variations have been noticeable and the way these lab check findings translate to make use of on the path.

Lab Testing

I wasn’t current for the lab testing, however Simon Ayotte, Faction Bike Studio’s R+D Director who carried out the lab testing, gave me the step-by-step rundown.

-Place the handlebar within the desk clamp with the rise aligned vertically.

-Tighten screws to 5N.m.

-Put the burden clamp 65mm from the tip of the handlebar. (alter for bar size for consistency)

-Put the burden (42kg or 92.6 lbs) on the hook of the clamp. Notice deflection.

From Simon: “We measured to be sure that the deflection was linear (like a coil spring), so it didn’t actually matter the burden we selected, however we ended up with 42kg as a result of that’s what we had mendacity round and it made for sufficient deflection to make measurements straightforward. One factor that’s essential to notice, is that we tailored the place we put the load relying on the bar size, so all measurements are comparable. Our baseline was 800mm bar width, the place we put the load 65mm from the ends. So, for instance, if we have now an 820mm bar, we alter the measure to 75mm, if the bar is 760mm vast we alter the measure to 45mm. This manner all deflections measured are “adjusted” for a standardized 800mm width.”

This straightforward check offered a comparability of the compliance of every bar given the identical quantity of weight utilized. The quantity of deflection (flex) was recorded and a stiffness ranking, which is basically a spring fee, was given to every handlebar. Spring fee is the fixed quantity of drive it takes a compression spring to journey an inch of distance, (or if utilizing the metric system, a millimeter of distance). Because the metric numbers are fairly small, we selected to precise this in lbs/in in order that the variations are extra readily obvious.

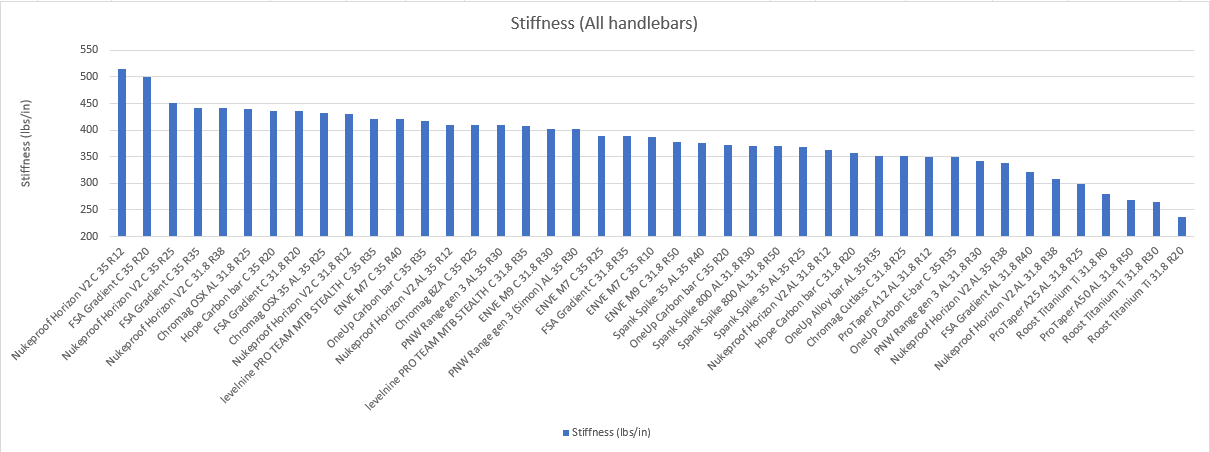

For comparability, probably the most compliant bar we examined, the Roost Titanium (31.8mm clamp, 20mm rise) has a spring fee of 237 lbs/in (4.24 kg/mm), whereas the stiffest bar we examined, the Nukeproof Horizon V2 Carbon (35mm clamp, 12mm rise) has a spring fee of 515 lbs/in (9.19 kg/mm). That means that it takes greater than double the drive for the Nukeproof bar to flex the identical quantity because the Roost.

Rider Testing

The second side of our testing was to carry out blind rider testing to see if the variations in handlebar compliance have been noticeable, and what, if any, affect it had on our consolation and management whereas driving. To do that, a choice of 4 handlebars have been chosen from the check group together with the stiffest, most compliant, and two that fell barely above and beneath the typical to symbolize the vary of compliance. We assigned compliance scores (0-10) primarily based on the place they fell on the compliance scale from the lab testing.

Again in October, I met Faction Bike Studio’s product supervisor, Adam Robbins, together with the R&D Director, Simon Ayotte, for a day of handlebar testing at Bromont, QC. I’d wish to level out that each Adam and Simon completely rip on mountain bikes and it was enjoyable attempting, and failing, to maintain up with them whereas we have been testing. Faction Bike Studio’s design workplace and check lab is situated close by in Granby, QC, and Bromont is the closest and greatest driving within the space and arguably all of southern Quebec. (It’s undoubtedly a few of the greatest driving I’ve accomplished on the East Coast, and I grew up there!)

Bromont boasts an unimaginable quantity and number of trails, from machine-built move to technical hand-built East Coast chunk. A number of chairlifts function all summer time for entry to the bike park, and there are designated climbing routes for these accessing the paths beneath their very own energy or driving e-MTBs. There’s one thing for everybody, from learners to seasoned execs. In reality, Bromont has even hosted quite a few World Cup Downhill races over time.

Sadly, our late October timing meant that the lifts had closed for the season the week earlier than our testing, so we ended up climbing for every of our handlebar check laps. On the flip facet, we additionally occurred to be driving in the course of the absolute peak of the autumn foliage, so none of us actually appeared to thoughts the additional effort it took to pedal to the highest.

Simon, Adam, and I all rode a management lap with our common handlebars, to familiarize ourselves with the path and have a baseline to check to the opposite bars. Since Simon knew the outcomes of the lab testing, he performed the position of motorcycle mechanic, swapping them out after every run and ensuring to cowl them in order that Adam and I have been unaware of the model, mannequin, materials, and clamp diameter. A easy however efficient part of a bicycle interior tube was used to obscure the handlebar and stem from our view. Simon additionally took nice care to make sure that our bar peak, roll, and the setup of our controls have been constant each time.

Driving the totally different bars again to again offers the chance to straight examine the best way they really feel on the path. Adam had chosen a superb check lap for us that featured all the things from sweeping berms, steep rock slabs, chunky technical sections, and loads of pace. This check lap offered us the chance to make use of every handlebar on the very same observe to evaluate their efficiency in the identical compressions, chatter, and dealing with situations. He additionally confirmed up early on the day of testing and walked the entire path with a battery-powered leaf blower to clear it of all of the just lately fallen leaves. Thanks Adam!

What We Discovered

For everybody concerned, I believe there are fairly just a few takeaways from this undertaking. In the beginning, there are comparatively vital variations in compliance throughout the bars we examined. These variations are, the truth is, fairly noticeable out on the path, significantly when driving bars on the extremes of the stiffness/compliance reduce to again. The nearer you get to the median, after all, the much less apparent these variations change into. And, whereas a bar might really feel too compliant or too stiff initially, it doesn’t take too lengthy to get used to it even when it isn’t essentially superb.

Common Tendencies

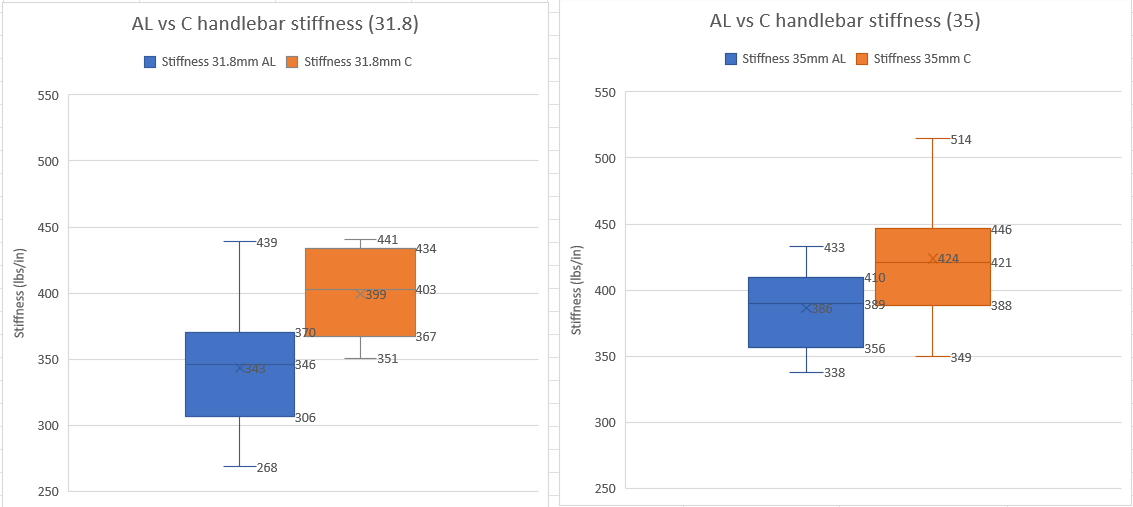

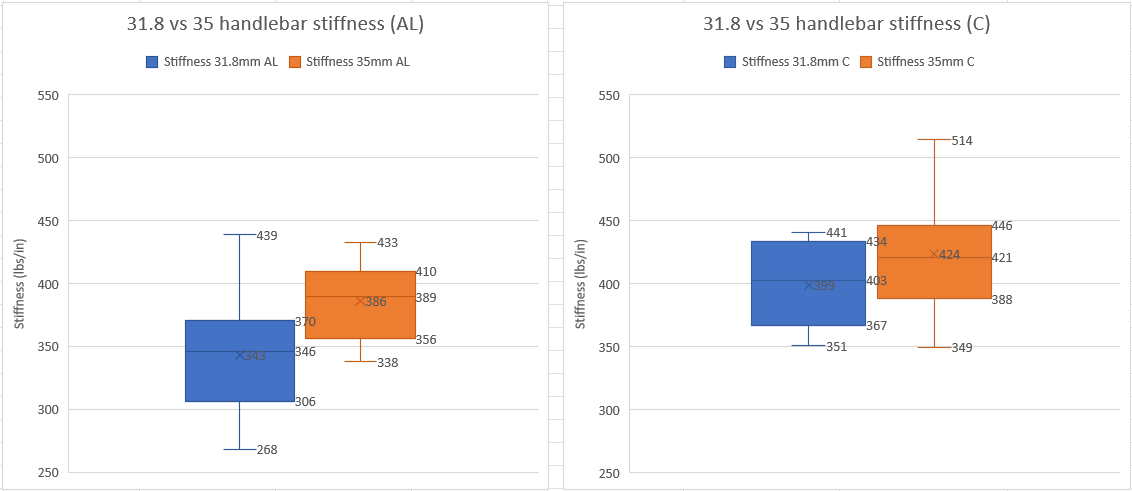

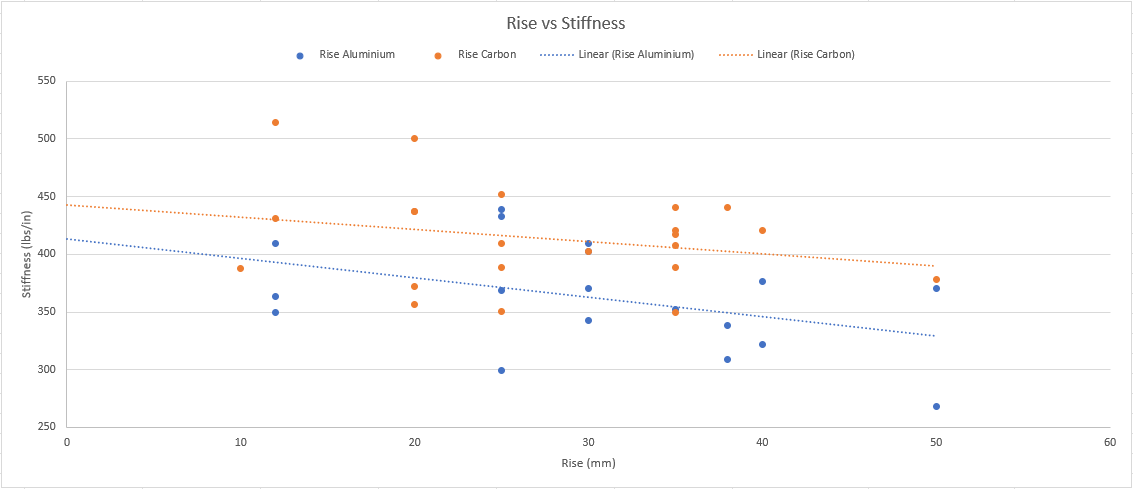

The outcomes of our lab testing revealed some normal tendencies relating to the stiffness/compliance of handlebars constructed from totally different supplies and with totally different clamp diameters. By merely calculating the averages of all of the fashions we examined (separated by materials and clamp diameter), we discovered that handlebars constructed from carbon fiber are barely stiffer than these manufactured from aluminum and that bars with a 35mm clamp diameter are barely stiffer than these with a 31.8mm clamp diameter.

In fact, these are very broad brush strokes and the tendencies are simply contemplating the averages. Inside every class of clamp dimension and materials, you’ll find bars which can be stiffer or extra compliant (not counting the Titanium fashions). In reality, the sixth stiffest bar we examined was the Chromag OSX Alloy 31.8mm R25, and the ninth stiffest was the Chromag OSX Alloy 35mm R25. That stated, the opposite eight of the ten stiffest bars have been carbon fiber, 6 of which had a 35mm clamp diameter, 4 of these have been Nukeproof Horizon V2 Carbon, and three of them have been FSA Gradient Carbon fashions.

On common, handlebars constructed from Titanium (not less than the three Roost fashions we examined) are considerably extra compliant than these constructed from different supplies by roughly 30%. The 2 most compliant bars we examined have been the Roost Titanium R20 and R30, and the R0 was fourth. This is smart given Titanium’s status as a frame-building materials for offering a extra forgiving trip high quality, however even then, I didn’t anticipate them to be that compliant regardless of that being one in all Roost’s major promoting factors.

Variability

We additionally discovered that there’s fairly a little bit of variance among the many identical mannequin of handlebar in numerous clamp sizes, supplies, and rise measurements. This stands to motive on condition that including bends, altering the dimensions of the clamp interface, or utilizing a unique materials will seemingly have some measurable affect on its skill to flex beneath weight. However, what that tells us is that you just shouldn’t routinely anticipate the identical handlebar to really feel precisely the identical throughout totally different supplies, clamp sizes, or rise dimensions. The exception to this rule is the 4 Spank Spike Alloy fashions we examined, which have been almost similar no matter rise or clamp diameter.

It is usually price mentioning that we solely examined one pattern of every handlebar mannequin within the lab, so our findings don’t take manufacturing variability under consideration. For instance, the FSA Gradient Carbon (35mm clamp, 20mm rise) we examined within the lab was the 2nd stiffest bar (500 lbs/in), and the identical mannequin as Adam’s private bar. Later lab testing of Adam’s private bar revealed that it truly measured the identical because the Chromag OSX (31.8mm clamp, 25mm rise) we rode within the video (438 lbs/in). Apart from the potential for some stiffness of carbon parts to be misplaced over time on account of fatigue (although we are able to’t verify the speed or degree to which this occurs), we really feel that is extra seemingly the results of manufacturing variability.

Supplies

Compliance alone isn’t the one issue dictating how forgiving a handlebar feels. It does play a serious position in absorbing a few of the brunt of bigger impacts like these usually related to driving mountain bikes, after all, however totally different supplies take in high-frequency vibration to various levels. It’s right here that carbon fiber bars have the higher hand, and private expertise has proven that some carbon handlebars present a extra damp or muted really feel when in comparison with aluminum choices with the identical degree of compliance.

Faction Bike Studio’s R&D Director, Simon Ayotte, offered somewhat rationalization. “The numerous tiny interfaces in a composite bar damp out vibrational power a lot better than a steel half (whether or not bar, body, fork or seatpost). It has been clearly proven in testing carried out prior to now on the Universite de Sherbrooke. That is the explanation that the majority aluminum bikes are bought with carbon forks – forks and bars are areas the place vibrations are readily transferred to the rider and so composite components in these areas present very noticeable advantages in trip really feel and high quality. It must also be famous that the vibration-damping impact comes from the composite construction and never particularly carbon fibres. The consolation results talked about are primarily based extra on the high-frequency results of street driving.”

So, whereas this undertaking confirmed that the findings of the lab-based compliance testing did translate on to how totally different handlebars really feel on the path, we additionally acknowledge that there are additional assessments that may be accomplished particular to mountain bike handlebars and totally different supplies’ skill to soak up high-frequency vibration.

Match

A handlebar’s form and, extra particularly, its ergonomics, play an equal or probably higher position in rider consolation. Even the slightest adjustments to rise, sweep angles, width, and handlebar roll can alter your physique place and wrist alignment in methods that may positively or negatively affect each your consolation and efficiency on the bike. There isn’t a one-shape-fits-all, so it’s essential to seek out what works greatest on your particular anatomy.

What’s Greatest?

There isn’t a proper or unsuitable, higher or worse. In fact, a sure degree of stiffness or compliance could also be higher or worse for you relying in your preferences, however that’s the great thing about having so many choices. You possibly can select what works greatest for you whether or not that’s a supremely stiff Nukeproof Horizon V2 Carbon, a considerably extra compliant Roost Titanium bar, or one of many many choices that land someplace in between.

As for me, I’m sticking with my OneUp Carbon handlebar as a result of it really works nicely for me. It lands roughly in the midst of the compliance scale of all of the fashions we examined and I really feel it delivers an exceptionally balanced trip really feel. It’s not almost as compliant within the flex check because the Roost Titanium bars, however I personally really feel prefer it manages to mute high-frequency buzz and suggestions as nicely or higher than the rest I’ve tried. Whether or not that has one thing to do with the ovalized rise part or carbon’s skill to soak up vibration otherwise, I’m not totally certain. Possibly it’s simply my notion or the placebo impact? Regardless, it’s light-weight, appears to be like good, and I identical to it.

About Faction Bike Studio

Faction Bike Studio was based in 2010 and is situated in Granby, Quebec, about an hour east of Montreal. Faction is an unbiased design, engineering, and testing firm that works with many manufacturers throughout all features of the biking trade from street, gravel, and mountain bikes to parts, equipment, electrical bikes, and micromobility tasks.

Faction Bike Studio gives a variety of companies together with technique, design, product improvement (together with prototyping and lab and subject testing), industrialization/manufacturing, and even model technique and advertising and marketing. Faction has a full-time workers of 33 designers, engineers, testers, and extra who work with manufacturers to take merchandise from idea to actuality.

Faction operates primarily behind the scenes and offers companies from ideation to manufacturing for a lot of manufacturers within the biking trade. As such, their work is in every single place, together with UCI and Enduro World Cups, and the Olympics, regardless that it might not be obvious to the informal observer, and their work has earned them quite a few design and engineering awards over time.

One of many extra seen tasks that Faction has labored on that many individuals could also be accustomed to is Neko Mullaly’s Frameworks bikes. Current posts on Instagram have proven this partnership and Faction Bike Studio’s position within the engineering assist and prototyping of the newest bonded Frameworks check bikes.

To study extra about Faction Bike Studio and the companies they provide, go to factionbikestudio.com